We take iconic jacket styles and re-make them using the best materials that we can find.

All of our jackets are made to order, in limited edition batches, just four times a year. It's our way of making sure we create no waste.

Each jacket we make is designed by us in East London before it gets made by a small family run factory in Northern Portugal. Each one is hand numbered in the order it’s sold. Illustrated labels on the inside tell the story of that Batch, plus details that most brands would cut out.

All jackets are currently sold out. Visit the Archive to see everything we've made, or keep reading to learn more.

Before we tell you about jackets, it’s probably worth setting the scene so you know where Paynter came from.

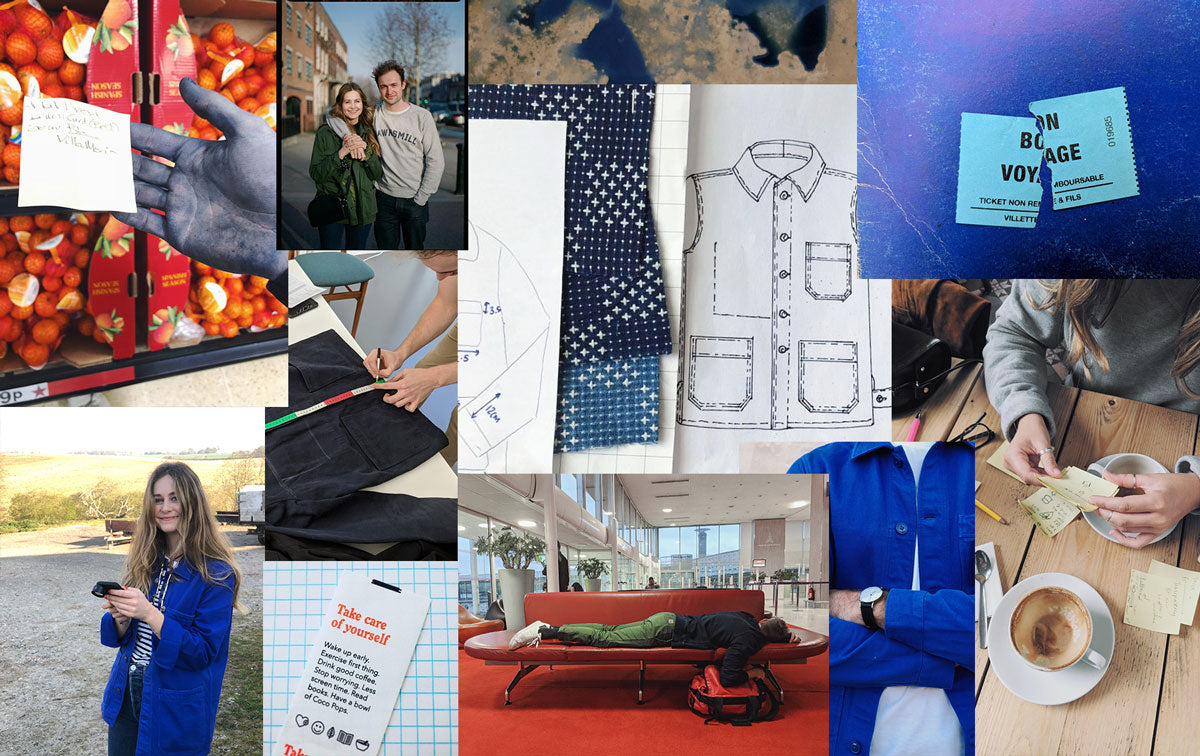

Huw and I met in 2018, at a workshop in London. My boss was on the workshop and felt ill, so I said I’d cycle over and take notes. For some reason I’ll never know, I walked in and gave Huw a hug. We’d never met before... Good energy?!

Luckily, we got on well. The next day I went surfing for 2 weeks. We messaged everyday. The week I got back I headed up to North Wales to see my family, and Huw joined us for 3 days. Yup, our first date was 3 days long. It was either going to be a disaster, or great. We figured at worst it would be a funny story to tell friends, but luckily, so far so good.

The normal thing would have been to get to know each other slowly, go for walks, have coffee dates, watch Netflix. You’re probably wondering why that’s relevant. Well, it sums up how we’ve gone about starting this project, so I thought it might put things in context. We tend to jump in and work out what to do about it later.

"100 billion items of clothing are made every year. 62% percent end up in landfill"

On day number 2 of our first date extravaganza, we started talking about brands. What we liked, what didn’t feel right, what we were bored of and wanted to see more of. We got onto what we’d each want if we had a brand of our own. We definitely didn’t want to create stuff people didn’t want. We wanted to create something small and interesting.

Fast forward a few weeks and we’re back in North Wales. This time, Huw whips out an amazing vintage blue jacket. That jacket was one of a few workwear jackets he’d been collecting. Huw had been making his own jackets since before we met, using scraps of raw denim from underneath the cutting table at Hiut Denim.

He'd bought the jackets to take apart, to learn how they were constructed, so he could remake the iconic French workwear jacket. But, that blue jacket was too special to cut up. It was a slimmer fit than your average boxy jacket. It was softer and obviously made to last. But, like most side projects, Huw had got busy, and put his jacket project to one side.

After that weekend I took the jacket back to London for safe keeping, and soon enough, we decided to give it another go. We’d re-make this iconic jacket, using beautiful materials, and we’d create a brand around the jacket. What else do you do, when you’re in the first few months of a new relationship, you’re both working full time, one in London and the other in Cardigan… it's a no brainer, right?!

Step 1. Find someone who could help us make a pattern. An old flatmate gave me the phone number of a retired man called David who was supposedly great. I called him, and we had a great chat so we had a good feeling. He said he’d meet us at the train station on Saturday morning. True to his word, at 10am sharp, David pulls up in his Honda jazz and we get into the car of an elderly man we’ve never met, to drive to his house and meet his wife, Gina. We ate croissants together in their living room and made small talk about where they’ve worked and how they met. David helped us create our first pattern. And we found out he used to work at Burberry, so we knew we were in good hands.

Step 2. We had our pattern, so we needed to find our maker. So we headed to Paris for 24 hours, to go to a trade show called Premiere Vision. A ginormous trade show, with halls and halls of everything you could need if you work with product. Armed with 1000 business cards and nothing else, we talked to loads of mills and makers, and we found one man, our needle in a haystack, who made the entire trip worth it.

Factories don't like to work with new brands. New brands don't have an established history, wholesale orders or loads of cash. But Sergio said he could see something in us, and he agreed to take the risk of working with us to make our jackets. Sergio's family have a factory in Portugal, in a town just outside Porto called Guimaraes. It’s a beautiful, small town, a proper making town.

While Sergio got to work making our first sample, we had a lot of work to do behind the scenes. We were teaching ourselves (and still are) brand design, sourcing & manufacture, fabrics, details, cash flow and everything else you can think of.

We wanted to show the entire creative process, with nothing held back, so we've documented every step of setting up Paynter via our Instagram and email newsletters.

For example, when we got the first samples back from Sergio, the colours were really dodgy, so we dyed over the blue with a natural indigo. Huw’s arm hair was blue for weeks. Luckily we’ve now been able to dye our jackets bespoke to the exact Pantone references. Much better for Huw’s arms.

We sent handwritten letters to illustrators, explaining our concept for limited edition jackets and we asked if they’d like to be involved. Chris DeLorenzo made four amazing drawings to illustrate the stage that we were at, at the very beginning.

Creatives hate talking about money. So we talked about money. Our friends asked how we could afford to pay for samples, to go to Paris etc, so we decluttered our lives, and sold a lot of stuff on eBay. It meant a lot of trips to the post office, reevaluating how we spend money, and calculate value.

Weeks and months of wear testing taught us what we liked, whether the sizes of pockets were right, how was the sleeve length, body fit, fabric quality, inside pockets, the height of the pockets... You have no idea what’s right until you’ve worn something a fair few times.

A few samples in, we were getting really close, but we wanted to make final tweaks. So we went to Porto for 2 days to meet the rest of the makers at our factory. Face to face meetings are better than a thousand emails.

We also visited the garment dyers, 20km from our factory.

We absolutely love factories.

While we were there, we asked a lot of questions. We learnt that a lot of workwear brands sold in London were made in our factory and used one of two fabric options. There was a light-medium weight option, and a medium-heavy weight option. When we asked about the origin, it was clear that the supplier of both fabrics was not based in Portugal, and the original mill wasn't known. That didn't feel good enough.

And so Batch No.1 took a pause while we explored better options for sourcing our fabrics. We looked for mills who we could trust to provide beautiful fabrics that would last a lifetime, and who were honest about the origin of their materials. We discovered Berto, a mill just outside Venice, who have been making fabrics for sails and workwear since the 1850s. Together we created a bespoke Reverse Bull Denim for Batch No.1, that took 10 weeks to weave especially for us to make just 300 jackets in total.

By the time it was ready, 2,500 people found our project interesting enough to join a wait list for our first jacket. And since then we’ve kept making limited edition jackets and each one has sold out in under an hour. Slow decisions and a lot of wear testing meant taking 9 months to get one product just right. Selling just 4 times a year means we can spend 99% of our time learning to make a better product with a smaller impact.

If you’ve enjoyed our story so far, you might like to join our community and subscribe to our newsletter. Thanks for joining us.